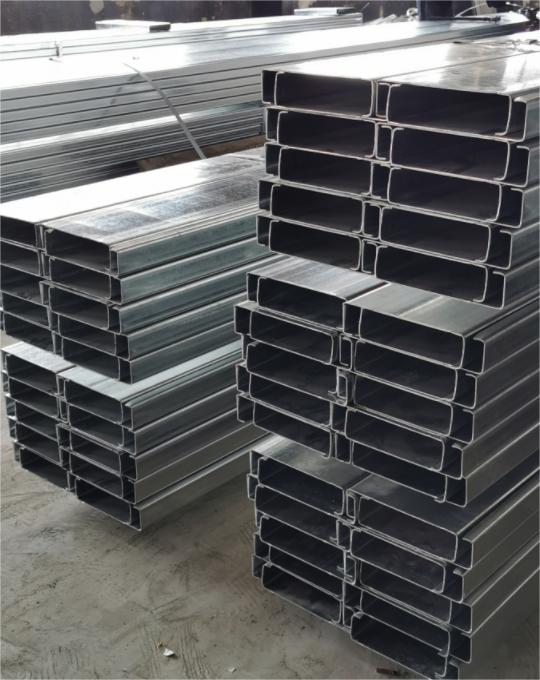

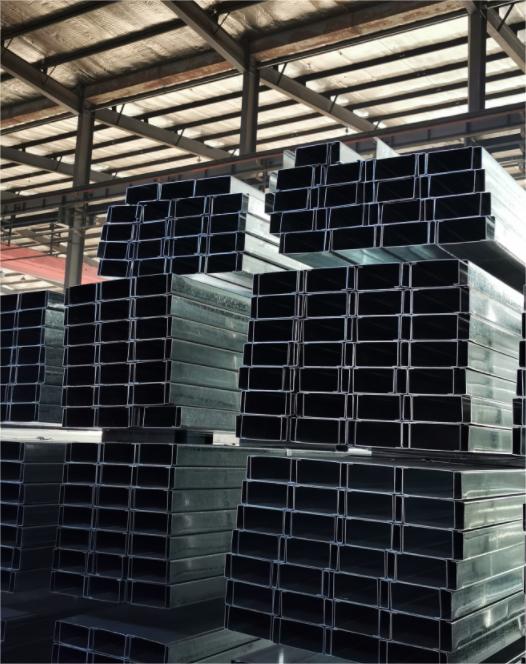

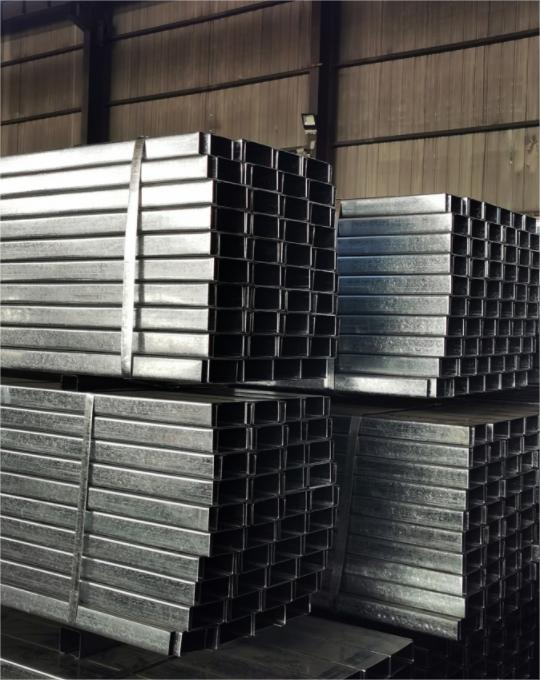

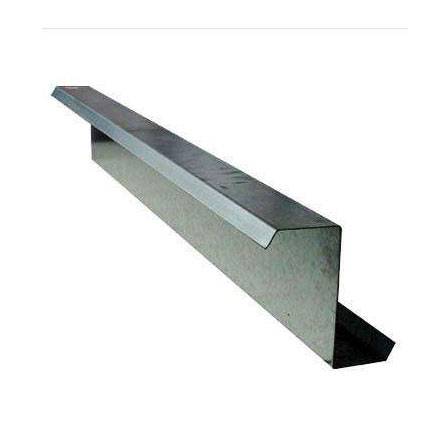

Hlau Fabricated CZU

Cov txheej txheem ntau lawm yog dab tsiCold Formed Section Steel?

Cov txheej txheem ntawm cov tshuab txias-dov strip mills feem ntau tswj kev npaj billet, pickling, txias dov, annealing thiab xov.

Kev npaj dawb paug yuav tsum muaj cov tshuaj lom neeg muaj pes tsawg leeg, qhov dav thiab tuab (peb qhov sib txawv thiab tib kab sib txawv), thiab qhov khoov khoov yuav tsum ua tau raws li qhov yuav tsum tau ua, thiab qhov saum npoo yuav tsum du thiab tsis muaj kab nrib pleb, folds, delamination, pores, tsis- metallic inclusions, thiab lwm yam.

Sawb steel yuav tsum ncaj thiab pob tw welded ua ntej pickling rau successive pickling.Lub hom phiaj tseem ceeb ntawm pickling yog kom tshem tawm cov hlau oxide nplai.Thaum lub sij hawm pickling txheej txheem, lub concentration thiab kub ntawm cov kua qaub thiab cov ntsiab lus ntawm ferrous ntsev nyob rau hauv cov kua qaub yuav tsum tau tswj.

Txhawm rau tswj cov tuab thiab phaj zoo, qhov txo qis, nrawm, nro thiab yob cov duab yuav tsum tau kho.Lub thickness yog tsuas yog tswj los ntawm AGC, thiab cov duab ntawm lub phaj yog tsuas yog tswj los ntawm kev kho cov yob profile (yob crown thiab crown them txoj kev), xws li HC, CVC, thiab lwm yam.

Annealing yog muab faib rau hauv nruab nrab annealing thiab tiav annealing.Center annealing yog tshem tawm ua hauj lwm hardening, thiab cov khoom annealing yog kom tau cov qauv thiab kev ua haujlwm.Annealing furnaces muaj xws li kev sib txuas ua ke rau qhov cub tawg thiab lub tswb nrov annealing furnaces.Cov txheej txheem annealing ntawm lub tswb-hom annealing rauv yuav tsum tswj qhov feem ntawm cov roj tiv thaiv hauv lub cub tawg, lub sijhawm cua sov, thiab lub sijhawm txias;cov txheej txheem annealing ntawm lub qhov cub ua tiav annealing yuav tsum tswj qhov kub, ceev, sijhawm thiab cua raws li qhov nkhaus annealing.Tswj cov sawb nro nyob rau hauv lub cub tawg kom ntseeg tau lub phaj zoo, thiab tswj lub cub tawg yob yas kom tsis txhob sawb sib txawv.

Finishing muaj xws li flattening, txiav, oiling thiab ntim.Flatness tuaj yeem txhim kho cov duab ntawm lub phaj, ntxuav qhov chaw thiab tau txais cov haujlwm uas yuav tsum tau ua.Cov txheej txheem flattening yuav tsum tswj lub elongation ntawm lub sawb, thiab lub shearing yuav tsum tsuas yog tswj lub teev thiab nto zoo, cov roj yuav tsum uniform, thiab lub ntim yuav tsum tau raws li cov kev cai, uas yog conducive rau cia, tsheb thauj mus los thiab xa.

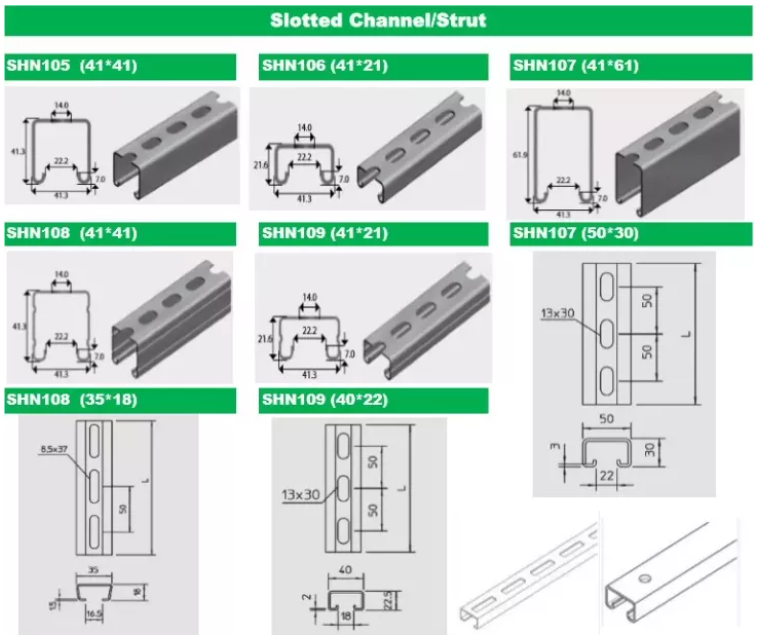

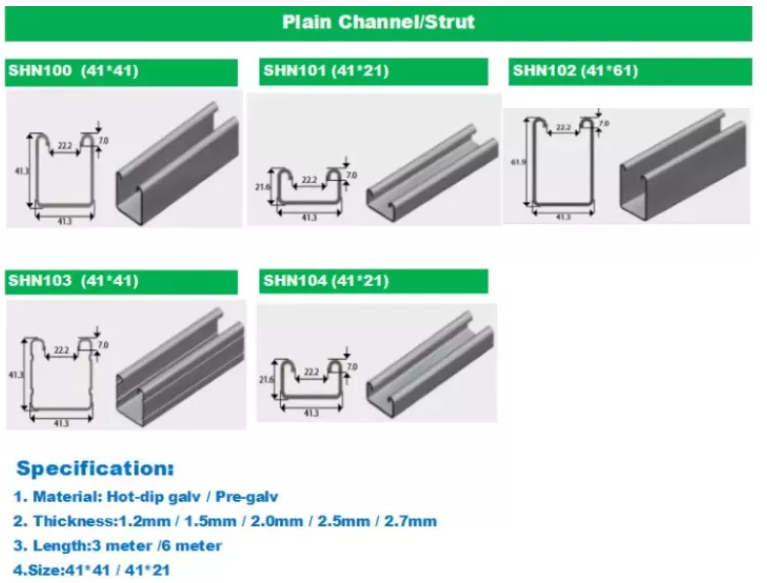

| TSIS MUAJ. | Loj | Thickness | Hom | Nto Kev kho mob | ||

| mm | Ntiv | Thickness | Ntsuas | |||

| A | 21 * 10 | 13/16 * 13/32 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| B | 21 * 21 | 13/16 * 13/16 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| C | 41 * 21 | 1-5/8 * 13/16 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| D | 41 * 22 | 1-5/8 * 7/8 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| E | 41 * 25 | 1-5/8 * 1" | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| F | 41 * 41 | 1-5/8 * 1-5/8 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| G | 41 * 62 | 1-5/8 * 27/16 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

| H | 41 * 82 | 1-5/8 * 3-1/4 " | 1.0, 1.5, 2.0, 2.5, 2.75, 3.0 | 19, 16, 14, 12 | Slotted, Khoom | HDG, PG, PC |

Tag nrhotxias tsim steel c profileyog zoo li tus tsis siv neeg ua los ntawm C-steel make-up tshuab, uas raws li muab C-steel ntau thiab tsawg, tuaj yeem ua tiav C-steel txoj kev tsim.

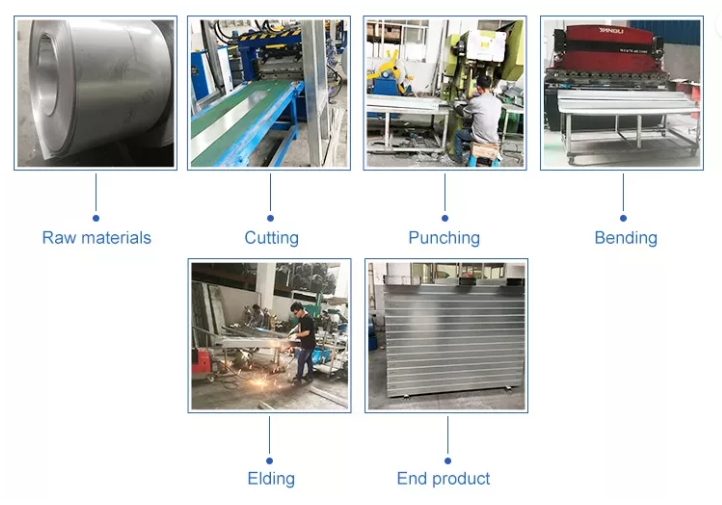

Pub-Flattening-Forming-Sizing-Aligning-Length Measurement-Punching Round Qhov rau Tie-bar -Punching Oval Txuas Qhov-Molding Txiav-tawm