Kub dip galvanizing (steel raj) tsim khoom

Pub → pickling, ntxuav → hnyav → ziab → kub dip galvanizing → sab hauv thiab sab nraud tshuab → dov daim ntawv lo, cim → passivation → tshuaj xyuas → ntim.

Tus neeg ua haujlwm thauj khoom yuav tsum xyuas cov khoom siv:

1. Sab nrauv ntawm cov yeeb nkab steel yuav tsum tsis txhob nplaum nrog roj (tshwj xeeb tshaj yog cov roj stains xws li asphalt oil blending paint), txwv tsis pub ntau cov khoom tsis tsim nyog yuav tshwm sim.

2. Cov yeeb nkab steel yuav tsum tau ncaj tom qab ntau lawm kom tshem tawm cov kev ntxhov siab sab hauv ntawm cov yeeb nkab steel.

3, steel tube nto tsis sib luag corrosion tsis tuaj yeem galvanized, txwv tsis pub ntau cov hydrochloric acid yuav nkim.

- Tsis muaj kev dag ntxias raug tso cai nyob rau hauv cov txheej txheem ntawm kev thauj mus los ntawm cov yeeb nkab steel.

5. Rau cov kav dej kub-dip galvanized steel kav, nws tsis raug tso cai los ua cov cim rau ntawm phab ntsa sab hauv thiab sab nrauv ntawm cov kav hlau steel kom tsis txhob xau plating.

1. Pickling ntawm steel yeeb nkab:

1) Pickling cov neeg ua haujlwm yuav tsum hnav cov khoom tiv thaiv kev ua haujlwm ua ntej ua haujlwm, ua tib zoo xyuas seb puas muaj qhov chaw ua haujlwm tsis muaj qhov thaiv thiab seb lub hlua puas tsis zoo, thiab tom qab ntawd ua haujlwm tuaj yeem ua tiav tom qab kev pom zoo.

2) Hydrochloric acid feem ntau yog siv rau hauv pickling, thiab hydrochloric acid yog npaj los ntawm dej.Cov ntsiab lus ntawm hydrochloric acid yog 18-20%, uas yog qhov tsim nyog dua.

3) Nkag siab txog acid concentration, kub thiab tonnage ntawm cov yeeb nkab pickling hauv lub tank ua ntej pickling.

4) Thaum nqa cov yeeb nkab, ob txoj hlua yuav tsum nyob deb li ntawm 1.3 meters ntawm qhov kawg, kom tsis txhob khoov cov yeeb nkab steel thiab ua rau cov dej xau hauv cov yeeb nkab galvanized; Thaum mus rau hauv lub raj mus rau cov kua qaub tank, cov yeeb nkab steel yuav tsum. tilted 15 °, thiaj li txo qis qhov kawg ntawm lub raj ua ntej, txhawm rau tiv thaiv cov kua qaub los ntawm cov neeg raug mob.

5) Txhua qhov pickling ntawm steel yeeb nkab yuav tsum nyob rau hauv qhov hnyav ntawm 2 ~ 5 tons thiab lub sij hawm ntawm 5 ~ 15 feeb.

6) Lub raj steel yuav tsum vibrate nquag thaum pickling.Nyob rau hauv cov txheej txheem ntawm kev vibration, lub raj steel yuav tsum tau muab tso rau ntawm kab rov tav pob zeb ntawm lub tank acid, thiab cov hlua ntawm ib sab yuav tsum tau pib dua 3 zaug, thiab tom qab ntawd cov hlua ntawm sab nraud yuav tsum tau pib dua 3 zaug. , thiab tom qab ntawd nqa tom qab rov ua dua ob zaug; Kev vibration nce lub kaum sab xis tsis ntau dua 15 °.

7) Thaum cov kua qaub ua kom sov, kho cov kav dej kom ruaj khov ua ntej qhib lub qhov cub.

8) Thaum lub crane crane nkag los yog tawm hauv lub tank acid, nws yuav tsum tsis txhob sib tsoo nrog cov phab ntsa ntawm lub tank kom tiv thaiv kev puas tsuaj rau cov kua qaub tank.

9) Cov laj thawj tseem ceeb ntawm kev pickling ntawm steel hlab:

(1) cov yeeb nkab steel yuav tsum tau soj ntsuam nruj me ntsis thaum pub mis, thiab cov yeeb nkab tsis tsim nyog yuav tsum tsis txhob muab tso rau hauv pickling.

(2) Cov yeeb nkab steel tsis ua haujlwm zoo thaum nws vibrates.

(3) Lub sijhawm pickling tsis txaus thiab cov ntsiab lus hydrochloric acid.

10) Cov laj thawj tseem ceeb ntawm steel tube pickling:

(1) Cov ntsiab lus hydroelectric acid ntau dhau.

(2) Pickling lub sijhawm ntev dhau lawm.

11) Tom qab pickling, xyuas seb lub npoo ntawm cov yeeb nkab steel puas yog du, seb puas muaj cov hlau seem seem thiab seb cov yeeb nkab steel puas yog cov pa phem los ntawm cov roj.

2. Kev ntxuav dej ntawm cov raj steel:

1) Kev ntxuav dej ntawm cov yeeb nkab steel yuav tsum tau nqa tawm hauv lub tank dej ntshiab.Soak tag nrho cov yeeb nkab steel hauv dej thaum ntxuav, so cov hlua khi thiab tshem tawm thiab tawm rau peb mus rau plaub zaug.

2) Tom qab ntxuav, cov dej hauv lub raj hlau yuav tsum tau tswj thiab kho nrog cov kuab tshuaj kom sai li sai tau los tiv thaiv oxidation ntawm lub raj hlau.

3) Cov ntsiab lus ntawm hlau thiab ntsev nyob rau hauv cov dej ntxuav yuav tsum tsis txhob tshaj tus qauv, thiab yuav tsum tsis txhob muaj lwm yam sundries.Nws yuav tsum ua kom huv si thiab pob tshab.

4) Thaum ntxuav cov yeeb nkab, nws yog nruj me ntsis txwv tsis pub cov neeg tsav tsheb hla lub tank pickling kom tsis txhob ntog los yog poob rau hauv lub tank ua rau neeg mob.1.Thaum lub raj steel nkag mus rau hauv cov kuab tshuaj tank, loosen lub sling thiaj li hais tias lub steel raj yog immersed nyob rau hauv cov kuab tshuaj kiag li.Qhov saum npoo ntawm lub raj steel tsis tso cai kom nthuav tawm cov kuab tshuaj ntog.Txawm li cas los xij ntawm ob qhov kawg ntawm lub raj steel tsis muaj npuas, ib sab ntawm lub raj steel yuav tsum tau nqa mus rau hauv siab kom vibrate, thiab lub raj steel yuav tsum tau nqa mus rau. tswj cov kuab tshuaj huv huv thiab tom qab ntawd nkag mus rau hauv lub rooj zaum kom qhuav.

2. Lub kaum sab xis ntawm cov yeeb nkab steel yuav tsum tsis txhob siab tshaj 15 ° hauv cov txheej txheem kho cov kuab tshuaj.

3, lub raj steel nyob rau hauv cov kuab tshuaj immersion lub sij hawm ntawm 60 ~ 120 vib nas this, rov qab raj immersion 3 ~ 5 feeb, rov qab raj immersion 5 ~ 10 feeb.

4. Qhov kub thiab txias: Khaws cov kuab tshuaj kom huv ntawm chav sov.

5. Tom qab kev kho cov kuab tshuaj, tsis txhob lo rau lwm cov av, tsis txhob ntub dej, muab tso rau hauv lub rooj ziab kom qhuav; Cov neeg tsis raug tso cai los ntawm cov yeeb nkab steel uas muab tso rau ntawm lub rooj kom qhuav.Yog tias nws yuav tsum tau nqis los, ob txhais taw yuav tsum tau coated nrog ammonium chloride ua ntej ua haujlwm ntawm cov yeeb nkab.1.Tom qab tsim nyog kho cov kuab tshuaj, muab lub raj steel rau ziab thiab tau txais lub platform, thiab muab lub raj steel rau pem hauv ntej ntawm lub lauj kaub zinc thiab sab pem hauv ntej ntawm ob lub sib nqus cov menyuam mus rau square ntawm lub kaum sab xis; Qhov ntau nkhaus yeeb nkab yog muab tso rau. nyob rau hauv lub nraub qaum los yog ncaj thiab muab tso rau ntawm qhov chaw txais khoom.

2. Lub luag haujlwm tseem ceeb ntawm kev ziab KANG yog kom qhuav cov dej ntawm cov yeeb nkab steel.Ntawm qhov tod tes, nws yog txhawm rau txhim kho qhov kub ntawm lub raj steel nws tus kheej, tiv thaiv zinc spattering los ntawm kev ua phem rau tib neeg, thiab tsis txhob tshem tawm cov cua sov hauv lub lauj kaub zinc, thiaj li ua kom cov zinc-ferroalloy txheej txheej.

3. Lub ziab kub ntawm kang yog 80 ℃ ~ 180 ℃, thiab lub sij hawm ziab ntawm steel yeeb nkab yog 3 ~ 7 feeb.Lub tshuab ziab khaub ncaws kuj tseem tuaj yeem tswj tau raws li cov lus qhia tshwj xeeb thiab cov phab ntsa tuab ntawm cov yeeb nkab steel.Cov tshuab ziab khaub ncaws yuav tsum tshawb xyuas qhov ziab ntawm cov yeeb nkab steel txhua lub sijhawm los tiv thaiv qhov tsis muaj sij hawm rau zinc kua txaws zinc raug mob; Thaum ziab, ua Tsis pub dhau qhov kub thiab txias, tiv thaiv cov kuab tshuaj ci coke.Qhov kub-dip galvanized steel yeeb nkab siv lub hauv paus ntsiab lus ntawm kev hu rau hauv, nias, spiraling, rub tawm thiab lifting nyob rau hauv txoj kev ntawm tag nrho dipping semi-automatic galvanized steel yeeb nkab kom tiav txheej txheem kub-dip galvanizing.

1. Kev tswj cov txheej txheem tsis: Qhov kub ntawm zinc tov yuav tsum tswj ntawm 440-460 ℃; Zinc dipping lub sij hawm yuav tsum tau tswj ntawm 30-60 vib nas this; Aluminium cov ntsiab lus (Zinc kua qib uas muaj txhuas 0.01-0.02%)

2. Zinc ingot yuav tsum yog zN0-3 zinc ingot nrog lub teb chaws tus qauv.

3. Tswj thiab tswj kev txhim khu kev qha ntawm lub unplugging thiab nias ntsia hlau thiab unplugging lifting ntaus ntawv tsis tu ncua, ntxiv dag zog rau lub lubrication ntawm lub tog raj kheej, kho qhov siab thiab lub kaum sab xis ntawm lub galvanizing yeeb nkab distributor zoo, thiab kho cov khoom mus rau lub zoo lub xeev.

4. Muab qhov sib thooj hloov kom raug; Thermocouple kab thiab meter yuav tsum tau siv nyob rau hauv tib lub qauv, txwv tsis pub, qhov kub thiab txias yuam kev yog loj, thermocouple tiv thaiv tes tsho, feem ntau xyuas thiab hloov.

5. Tus neeg teb xov tooj ntawm qhov chaw khiav hauj lwm yuav tsum manually kho qhov ceev raws li kev ua haujlwm ntawm cov khoom siv nyob rau hauv pem hauv ntej ntawm lub cub tawg thiab cov lus taw qhia kom tsis txhob muaj cov yeeb nkab txuas.

6. Preheat cov cuab yeej siv los ntawm cov neeg ua haujlwm hauv lub cub tawg ua ntej siv los tiv thaiv zinc spillage thiab raug mob; Nquag xyuas seb cov yeeb nkab steel puas poob rau hauv lub lauj kaub, yog tias muaj, kom tshem tawm hauv lub sijhawm; Txhawm rau kho kom raws sijhawm cov cuab yeej tsis txhob lo rau lub raj, kom muaj kev ruaj ntseg ntawm cov khoom siv.

7. Thaum ntxiv zinc rau lub lauj kaub zinc, cov zinc ingots yuav tsum tau preheated ua ntej.Tsis txhob tso cov zinc ntxiv, tsis pub ntau tshaj tsib daim zinc ntawm ib lub sij hawm.Nws yog txwv tsis pub tso cov hlau rau hauv cov kua zinc kom tsis txhob muaj zinc slag ntau.

8, thaum melting zinc yuav tsum maj mam rhuab, tsis txhob hlawv hluav taws, txwv tsis pub nws yuav ua rau lub neej ntawm galvanized lauj kaub, thiab muaj ntau zinc vapor volatilization.Thaum nqus tau pa ntau, cov pa phem no ua rau ib tug mob hu ua "foundry fever. ". Nyob rau hauv cov txheej txheem ntawm melting zinc, ib zaug zinc muaj qhov kub thiab txias yuav tsum tsis txhob kov cov zinc thaiv los ntawm tes, thiaj li tsis txhob kub hnyiab, yuav tsum siv cov cuab yeej tsim nyog los kov nws.

9, kom tsis tu ncua tshem cov zinc kua nto ntawm zinc ash.Thaum khawb cov tshauv yuav tsum maj mam muab tso rau saum npoo ntawm zinc kua nrog lub scraping phaj scraping swab, tsis tuaj yeem do ntau dhau, tsam cov zinc tshauv tsa, lub phaj scraping yuav tsum tsis txhob yuav. dipping zinc los yog tawm ntawm lub raj thaum lub steel tube sib cuag, thiaj li tsis mus yob tshaj qhov tshwm sim ntawm tus kheej raug xwm txheej los yog cov khoom raug mob.

10. Cov zinc blocks rau hauv av nyob rau hauv pem hauv ntej ntawm lub cub tawg, tawg zinc, zinc coj tawm thaum galvanizing, thiab zinc steel yeeb nkab ntws mus rau sab nraud yuav tsum tau rov qab los ntawm txhua lub sijhawm kom txo cov cua sov ntawm lub lauj kaub zinc.

11. Thaum cov txhuas ingots ntxiv rau saum npoo ntawm cov kua zinc, nws yuav tsum tau txav ntau zaus ua ntej thiab tom qab kom ntseeg tau tias cov ntsiab lus txhuas tsis sib xws ntawm cov kua zinc.

12. Txhawm rau kom yooj yim rau cov dej nkag thiab cov zinc rho tawm, 20 tons ntawm txhuas yuav tsum muab tso rau hauv lub lauj kaub zinc sab hauv.

13, slag dregs rau preheat lub dregs, zinc slag yuav tsum tau muab faib ua loj thiab me blocks cia, qhov kub ntawm lub dregs yuav tsum tau tswj ntawm 455 ℃ saum toj no, viav vias slag tshuab yuav tsum siv tshwj xeeb cov cuab yeej, deb ntawm lub zinc lauj kaub 1 meter, taw kom sawv ntsug hauv t-puab.

14, kub dip galvanizing txheej txheem yuav tsum nruj dua, yog li nyob rau hauv lub kub dip galvanizing ntau lawm txheej txheem, yuav tsum qhuav tag nrho chaw nres tsheb, uas yog hais tias, nyob rau hauv lub chav tsev lub sij hawm hauv paus tooj los yog tonnage ntau, tus nqi qis dua, thiab vice versa siab dua.1.Tom qab cov yeeb nkab galvanized tau muab tso rau pem hauv ntej, lub rooj sib nqus hlau nplaum yog siv los coj tawm cov yeeb nkab galvanized, thiab lub kiv puag ncig ntawm lub tshuab ua tsis tau nrawm, yog li ntawd cov zinc ntws huv si ua ntej lub tshuab ua haujlwm.

2. Lub kaum sab xis ntawm lub tshuab tshuab sab nraud yuav tsum tau sib npaug ntawm cov hlau nplaum rau ntawm cov ces kaum sab xis, thiab txoj haujlwm ntev thiab kev sib hloov yuav tsum yog qhov zoo los xyuas kom meej tias cov yeeb nkab galvanized hla nruab nrab ntawm lub nplhaib cua.

3. Thaum txhim kho cov hlau nplaum sib nqus, tsib lub tshuab hlau nplaum yuav tsum nyob rau ntawm txoj kab nruab nrab kom ntseeg tau tias cov zinc txheej txheej ntawm cov yeeb nkab sab nraud galvanized.

4. Sab nraud tshuab yuav tsum tau nqa tawm nrog cua compressed, nyiam dua 70 ℃, nyob rau hauv lub siab ntawm 0.2-0.4mpa.

5. Cua siab yuav tsum tau kho raws li nram no:

(1) Zinc txheej rau sab nrauv ntawm cov yeeb nkab galvanized yog tuab heev.

(2) Qhov saum npoo ntawm zinc txheej yuav tsaus tom qab tshuab sab nraud.

(3) Tom qab lub tshuab sab nraud, qhov saum npoo ntawm zinc txheej yog adhered rau sundries thiab strip cov khoom tsis huv.Cov huab cua ntim yuav tsum tau kho.

6. Hloov lub nplhaib cua ntawm tib qhov tshwj xeeb raws li qhov tshwj xeeb ntawm galvanized steel yeeb nkab.Lub nplhaib cua tsis tuaj yeem hloov tau los ntawm lwm qhov tshwj xeeb.

7. Nws yog txwv tsis pub hla cov yeeb nkab galvanized nyob rau hauv qhov xwm txheej tsis muaj cua, thiaj li tsis ua rau muaj qhov thaiv ntawm lub qhov cua thiab cuam tshuam rau qhov zoo ntawm cov tshuab sab nraud.

8. Nco ntsoov xyuas seb sab hauv ntawm lub tshuab tshuab sab nraud puas huv si, seb puas muaj zinc dai, txawm tias sab nraud ntawm cov yeeb nkab galvanized yog du thiab seb puas muaj khawb; Txawm hais tias lub npoo ntawm cov hlau nplaum, cov hlua txuas nrog zinc. , yog tias muaj kev txuas nrog zinc los ntxuav hauv lub sijhawm.

9. Vim tias tsis muaj cov hlau nplaum sib nqus thiab cov zinc txheej tsis ruaj khov, qhov saum npoo ntawm cov zinc txheej yog qhov feem ntau yuav raug khawb, yog li qhov ceev ntawm cov txheej txheem ntawm cov menyuam yuav tsum zoo sib xws nrog cov hlau nplaum sib nqus.1.Cov yeeb nkab kub-dip galvanized xa mus rau sab ntawm lub tshuab blower los ntawm cov khoom siv lead ua, thiab qhov sib thooj hloov tau siv los ua kom tiav cov kab rov tav txav, nias rau hauv lub tshuab nqus tsev, tsa lub taub hau siab, thiab txav mus rau qhov kub-dip galvanized. yeeb nkab rau hauv lub dab dej txias.

2. Lub raj kub coated yog qhov feem ntau yuav raug khawb ntawm lub rooj rau cov hlau lead.Qhov laj thawj tseem ceeb yog tias zinc tsis tau ua tiav tag nrho thaum lub sijhawm ua haujlwm ntawm lub raj.

3. Chav yog siv rau hauv tshuab, thiab lub tshuab nqus tsev siab yog 0.4-1.0mpa; Sab hauv ntawm cov yeeb nkab galvanized yuav tsum du.

4, galvanized yeeb nkab nyob rau hauv cov saw kom tswj tau ib qho qaij lub kaum sab xis, kom cov dej txias.

5. Qhov chaw ua haujlwm ntawm lub tshuab sab hauv yog nyob rau hauv qhov chaw ntxhab nrog qhov chaw ua haujlwm me me, yog li nws yuav tsum tau ua tib zoo ua haujlwm kom tsis txhob ntog, ntog thiab khoov raug mob; nruj me ntsis txwv ib feem ntawm lub cev, tiv tauj ncaj qha nrog kub kub galvanized yeeb nkab, kom tsis txhob raug mob.

6. Ua tib zoo saib seb koj ob txhais taw ruaj khov thiab muaj lwm yam teeb meem los tiv thaiv koj kom tsis txhob poob rau hauv lub dab dej; Nws yog ib qho yooj yim kom tawm cov saw hlau khiav ntawm lub dab dej, kom tsis txhob ya mus rau lub raj raug mob.Lub ntsiab lus: Thaum cov khoom yuav tsum tau khaws cia. thiab thauj mus ntev, passivation yuav tsum tau nqa tawm ntawm qhov chaw los tiv thaiv corrosion nyob rau hauv kev cia thiab kev thauj mus los.Cov khoom siv corrosion feem ntau hu ua dawb xeb.Cov txheej txheem passivation muaj xws li chromate thiab phosphate.

1. Passivation txoj kev: kub-dip galvanized yeeb nkab yog siv los tshuaj tsuag cov tshuaj passivation ncaj qha rau ntawm txoj kev khiav, thiab cov tshuaj yog wiped tawm ntawm ib tug deb ntawm ib tug meter los ntawm lub spraying txoj hauj lwm los ntawm chav riam.Ceev faj kom tshuab tawm cov tshuaj passivation.

2. So nrog compressed cua kom tshuab tawm cov kua nyob rau saum npoo ntawm lub raj steel thiab ua kom cov txheej txheej tsis sib xws.Los ntawm kev kho lub siab los kho lub thickness ntawm txheej, tsis muaj hlaws hlaws yuav tsum tau txuas rau saum npoo ntawm zinc raj. 1.Rolling mark thiab roller:

1) Thaum lub tshuab ntaus cim ua haujlwm, tsis txhob kov lub cim rau ntawm koj txhais tes los tiv thaiv tes nias; Nws yog txwv tsis pub hla ob lub yeeb nkab los ntawm lub tshuab ntaus cim kom tiv thaiv kev puas tsuaj ntawm cov xovxwm yob.

2) Thaum lub sij hawm ua hauj lwm ntawm cov yeeb nkab galvanized nyob rau hauv lub conveying roller rooj, lub tshuab cim yuav tsum hloov daim ntawv raws li txawv specifications, thiab qhov siab ntawm cov xovxwm log yuav tsum tau kho thaum lub specifications hloov, thiab roj yuav tsum tau ntxiv ntau zaus.

3) Lub nplhaib roj hmab ntawm lub tshuab dov npav yuav tsum tau kuaj xyuas thiab hloov lub sijhawm yog tias pom muaj qhov tawg.

4) Lub log roj hmab yuav tsum tau nias rau ntawm txoj kab nruab nrab ntawm lub raj steel, thiab lub sab sauv thiab qis kho bolts nrog lub siab zoo lub kaum sab xis yuav tsum tau kho.

5) Thaum luam tawm lub nplhaib logo, ob tus neeg yuav tsum yob tib lub sijhawm.Ink yuav tsum tau ntxiv ntau zaus kom yob cov yeeb nkab steel nrog kev xav, tab sis tus number case tsis yooj yim rau ntau dhau.

2. Ntim:

1) Lub baler SIV cua compressor roj, thiab lub siab yog 0.4-0.8mpa.Nws yog txwv tsis pub kov qhov txav ntawm lub baler nrog koj txhais tes kom tsis txhob ua mob rau koj ob txhais tes hauv kev ua haujlwm ntawm tus baler.

2) Thaum packing, thawj zaug muab cov buckles rau ntawm cov khoom siv, ces muab cov khoom siv nyob ib ncig ntawm cov yeeb nkab steel thiab ntxig rau lwm qhov kawg rau hauv cov buckles.Tom qab ntawd nias lub tshuab baling rau ntawm txoj siv packing thiab qhib cua valve ntawm lub tshuab baling rau packing thiab nias.Qhov tuab ntawm cov khoom siv yog 1.0-1.2mm.Lub packing siv yuav tsum yog 100 hli ntawm qhov kawg, 300 hli ntawm qhov thib ob, thiab 400 hli ntawm qhov kawg ntawm lub cim xiav xiav.

3) Xaiv cov packing khib ntawm tib qhov tshwj xeeb rau cov kav dej galvanized, muab cov kav dej galvanized rau hauv cov duab hexagonal thiab ua rau ib qho kawg.

4) Thaum sab nrauv ntawm cov yeeb nkab uas ntim cov hlau ua rau muaj kuab paug, ntxuav nws nrog cov xuab zeb huv si ua ntej stacking.Yog tias muaj kev tso cai, cov dej hauv cov yeeb nkab me me yuav tsum tau tswj hwm thiab ntxuav; Tsis txhob tso cai rau leej twg los nqis tes rau hauv lub raj nrog nws txhais taw, kom tswj tau qhov zoo ntawm galvanized raj zoo.

Tianjin Rainbow Steel Group yog cov kws tshaj lij steel khoom tsim khoom hauv Suav teb.

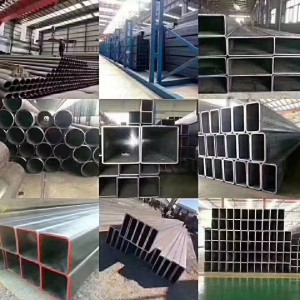

Cov khoom peb tuaj yeem tsim raws li hauv qab no:

Peb Cov Khoom Muag Khoom Loj:

1. Cov yeeb nkab steel(Round / Square / Tshwj xeeb zoo li tus / SSAW)

2. Hluav taws xob cov yeeb nkab(EMT/IMC/RMC/BS4568-1970/BS31-1940)

3. Cold formed Steel Section(C / Z / U / M)

4. Hlau Lub kaum ntse ntse thiab Beam(V Angle Bar / H Beam / U Beam)

5. Hlau Scaffolding Prop

6. Cov qauv hlau(Frame Works)

7. Precision txheej txheem ntawm hlau(txiav, straightening, flattening, nias, kub dov, txias dov, stamping, drilling, vuam, thiab lwm yam. Raws li tus neeg yuav tsum tau muaj)

8. Hlau Ntauwd

9. Hnub ci Mounting Structure

Peb lub tuam txhab Advantage:

1.Nqe:Peb lub tuam txhab nyob hauv Tianjin Tuam Tshoj.Tau ntau xyoo lawm, Tianjin tau ua lub chaw lag luam steel thiab qhov loj tshaj plaws steel yeeb nkab ntau lawm hauv Suav teb.Kev lag luam saw hlau thiab hlau khoom tiav;Nws muaj cov khoom siv loj thiab kev ua haujlwm ntawm no.Yog li cov yeeb nkab steel hom ua nyob rau hauv no ua tiav heev, qhov zoo yog super, tus nqi yog qhov zoo heev.Raws li ib pab pawg neeg tuam txhab, peb plaub lub Hoobkas tuaj yeem tau txais tus nqi zoo dua ntawm cov khoom siv raw vim qhov kev yuav khoom loj ntawm ib pawg ntawm cov ntaub ntawv.Tus nqi ntawm cov khoom xa tawm yog tag nrho cov nqi intro-pab pawg, yog li peb muaj tus nqi zoo dua lwm tus neeg xa khoom ywj pheej.

2.Kev thauj mus los:Peb cov mills tsuas yog 70km deb ntawm Tianjin Chaw nres nkoj, uas yog qhov chaw nres nkoj Loj tshaj plaws nyob rau sab qaum teb Tuam Tshoj, nrog cov nkoj xa mus rau ntau tshaj 300 qhov chaw nres nkoj hauv 170 lub teb chaws.Peb lub tuam txhab tsuas yog Nws yooj yim heev thiab txuag ob lub sijhawm thiab tus nqi hauv kev thauj mus los.

3.One Stop Service:Raws li ib pab pawg neeg tuam txhab, peb muaj plaub mills nrog ib tug niaj hnub warehouse & processing chaw, peb muaj peev xwm muab koj nrog ib tug ntau yam ntawm steel khoom: kub dov thiab txias tsim, nrog rau ib tug ntau yam ntawm cov tub lag luam bar, structural thiab tubular khoom.Peb muaj tag nrho cov khoom siv hauv tsev, kev lag luam thiab kev lag luam steel thiab cov kev pabcuam koj xav tau.Yog li yog tias koj yuav los ntawm peb, qhov peb tuaj yeem muab tau yog ib qho kev pabcuam steel khoom.Nws txuag tau ntau ntawm koj lub sijhawm yuav khoom thiab tus nqi tsim khoom.

4. Khoom Muaj peev xwm thiab xa khoom:

Peb muaj peev xwm ntau lawm, thiab xa tawm ntau tshaj 3500 tons hauv ib lub lis piam (ze li 150 20 GP thawv), Peb tuaj yeem xa cov khoom tsis pub dhau 20-30 hnub tom qab tau txais T / T tso nyiaj lossis L / C.Rau kev txiav txim ceev tshwj xeeb, peb tuaj yeem txo lub sijhawm ua ntej mus rau 10 hnub.

5. Ua raws li cov qauv sib txawv, Ua tau raws li cov qauv sib txawv:

Txij li thaum peb cov khoom tau raug xa tawm mus rau ntau lub teb chaws thiab cheeb tsam xws li Europe, Amelikas, Australia, Africa, Asia thiab lwm yam, peb cov khoom tuaj yeem ua tau raws li cov kev cai ntawm cov qauv sib txawv.Yog tias koj muaj cov cai tshwj xeeb, tsuas yog qhia rau peb, peb tuaj yeem tsim cov khoom lag luam customized rau koj, tsis tsuas yog ua tau raws li koj cov kev xav tau zoo, tab sis kuj txuag koj tus nqi ntau.

Peb cov neeg ua haujlwm paub txog thiab paub txog yog ib txwm npaj los teb koj cov lus nug txog peb cov khoom thiab cov kev pabcuam.

Tianjin Rainbow Steel Group Co., Ltd.

Xovtooj: 0086-22-59591037

Tus Fax: 0086-22-59591027

Xovtooj: 0086-13163118004

E-mail:tina@rainbowsteel.cn

Xov tooj: 547126390

Post lub sij hawm: Aug-17-2020